With the ongoing focus on the climate change crisis, reducing greenhouse gases and consequently Electric Vehicles, lithium batteries are being regularly referenced and have become the fastest growing technology in transportation.

However, lithium batteries are found in all facets of our everyday life and used as power sources for pacemakers, digital cameras, hearing aids, smart phones, PDA’s, remote car locks, calculators, laptops, toys and power tools.

Lithium can be used in a wide variety of chemicals and materials because of its enormous electro-mechanical potential. The fastest growing segments for lithium applications is in renewable energy storage and electric vehicles.

Though more expensive than ordinary lead acid batteries, lithium batteries have a significantly longer lifespan but are also less robust. It is the lightest metal in the element table and also the most chemically reactive which makes it a key ingredient in powering and building the latest electric vehicle technology. Lithium is silver-white in colour and when reacting with oxygen turns grey, its density is so low that it floats in water and its highreactivity allows it to burn while floating. Lithium’s exceptional reactivity is due to its single valence electron in its outer atomic shell. Lithium has the highest electric output per unit weight of any battery material.

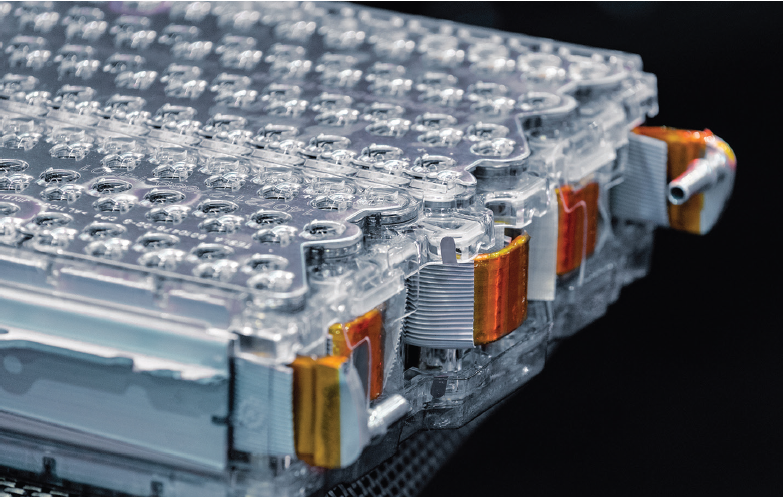

The inherent instability of lithium metal, especially during charging, requires a metallic solution using lithium ions. Lithium- ion, chemistries have become the most promising and fastest growing batteries on the market. Although lower in specific energy than lithium-metal, it is safe provided the current and voltage is limited. There are many different Lithium-ion combination chemistries, lets look at a few and their benefits and disadvantages.

TYPES OF LITHIUM-ION BATTERIES

Lithium-ion uses a cathode (positive electrode), an anode (negative electrode) and electrolyte as a conductor. The cathode is metal oxide and the anode consists of porous carbon. During discharge, the ions flow from the anode to the cathode through the electrolyte and separator; charge reverses the direction and the ions flow from the cathode to the anode.

When the cell charges and discharges, ions shuttle between cathode (positive electrode) and anode (negative electrode). On discharge, the anode undergoes oxidation, or loss of electrons, and the cathode sees a reduction, or a gain of electrons. Charge reverses the movement.

Most Li-ion batteries use the metal oxide positive electrode (cathode) that is coated onto an aluminium current collector, an anode made from carbon/graphite coated on a copper current collector, a separator and electrolyte made of lithium salt in an organic solvent.

There are six most common types of Lithium batteries. When assessing fit for purpose, the following areas must be considered:

• Specific Energy (kWh);

• Specific Power (kW);

• Safety;

• Life Span (cycle life);

• Overall Performance;

• and of-course cost

On the right-hand side is a table which highlights ratings for each of the key areas. Further below is a bar graph comparing most common battery technologies against one another.

In summary, LCO (Lithium Cobalt Oxide) excels on high specific energy but offers only moderate specific power, safety and life span. NMC (Nickel Manganese Cobalt) has good overall performance and excels on specific energy. This battery is preferred for electric vehicle applications and has the lowest self-heating rate. LMO (Lithium Manganese Oxide) is moderate in performance but newer designs have offered improvements in specific power, safety and life span.

LFP (Lithium Iron Phosphate) has excellent safety and is regarded as a consumer chemistry with a long life span but is moderate in specific energy and elevated self-discharge. It is the most consumer friendly lithium technology being utilised, particularly in 4WD applications for auxiliary power source for utility accessories such as light bars and winches as well as house batteries for caravanning, camping and boating.

NCA (Nickel Cobalt Aluminium Oxide) delivers the highest specific energy;however, manganese and phosphate are better with thermal stability. Li-titanate (LTO) has the best life span. Included for reference is the Nickel chemistries and Lead Acid Batteries (LAB). Lead acid is by far the most cost-effective option (around a third of the price), advanced batteries such as AGM and Gel are becoming popular and will continue to be the critical mass in the automotive aftermarket for some time to come. Maintaining the service life of any battery system does depend on the charging equipment and it’s important to note that charging a lithium battery requires a specific algorithm suitable to factor in the BMS (battery management system) and its own inbuilt protection protocol, so check that your charger is compatible.

Finally, Lithium batteries have heralded a new chapter in battery technology, launching batteries into the “smart” sphere to incorporate IoT or Internetof Things. Blue tooth communication capability is typically standard in high quality and well-known brands such as Lifeline. Remote access is enabled through the battery management system – an electronic component board with algorithms which calculates and communicates values such as:

• Voltage: minimum and maximum cell voltage

• State of charge

• Remaining capacity of the battery as %

• State of power

• Maximum charge current

• Maximum discharge current

• Energy delivered since last charge

• Total energy delivered since first use

• Total operating time since first use

• Total number of cycles

With cheap unregulated imports on the rise, it is important to research and talk to reputable suppliers. IP ratings, continuous current ratings, BMS compatibility, operating temperature and warranty should be researched.

Federal Batteries is a leading distributor of battery solutions serving the automotive, industrial, leisure and commercial industries since 1990. The company’s General Manager, Angela Schmidt, joined Bapcor in 2019 as a qualified Electrical Engineer bringing more than 25 years of experience across the mining, utilities, manufacturing, commercial and industrial sectors.

For any of your automotive battery requirements, contact Federal Batteries by calling 1300 133 980 or visit Federal Batteries online at www.federalbatteries.com.au