With a legacy in both aerospace and automotive industries, Garrett – Advancing Motion keep up to their reputation of revolutionising turbocharger technologies generation after generation.

The heritage of the Garrett – Advancing Motion turbo business began in 1936 when young Cliff Garrett formed his company in a tiny, one-room office in Los Angeles. With encouragement and financial support from friends like Jack Northrop and Harry Wetzel, Cliff founded the company that would later become the Garrett Corporation.

Through names such as AiResearch, AlliedSignal, and now Garrett – Advancing Motion Motion, the business has sustained a reputation for revolutionizing turbocharger technologies generation after generation.

Garrett – Advancing Motion Motion turbocharger technology is the preferred choice for leading original equipment manufacturers including Audi, BMW, GM, Daimler Chrysler, Mercedes, DDC, Fiat, Ford, International Truck Co, Peugeot, Renault, Saab, and Volkswagen. Top race teams in Formula 1, CART, World Rally, American Le-Mans, 24 Hours of Le Mans, Formula Drift, Global Time Attack, and Pikes Peak rely on Honeywell turbo technology to keep them on the podium.

Today, the Garrett – Advancing Motion Motion legacy in both aerospace and automotive industries helps create some of the most innovative and high-performing turbochargers in the world that can enable a four cylinder turbocharged engine to perform like a non-turbocharged V6 engine while providing 20-40 per cent greater fuel efficiency. Garrett Advancing Motion’s global engineering network continues to inspire technological innovation around the world.

A Turn Ahead Of The Competition Garrett® G Series Performance Turbochargers

Garrett® G25-550

Horsepower: 300 – 550

Displacement: 1.4l – 3.0l

The Most Powerful Small Frame Turbocharger on the Market Introducing performance out of a package you never thought possible. This clean sheet product is tailored to meet the demands of hard-core racing enthusiasts while providing industry leading power capability in a small package.

The G-Series G25-550 and the G25-660 turbochargers are compatible with 1.4L – 3.0L engine displacements and capable of producing up to 550 and 660hp. G Series 25 turbochargers are smaller and outflow all comparable products on the market.

New compressor and turbine aero combined with high-temperature resistant materials allowed engineers to push the limits of performance.

A new name designates a new generation of industry-leading technology and innovation.

Understanding the Name: G25-550 | G25-660

G designates 81 years of Garrett® heritage. 25 classifies the size of the frame. The remaining three digits identify the max horsepower rating of the turbocharger (i.e. 550).

Features include:

- Garrett® G series compressor aerodynamics for maximum horsepower

- Fully machined speed sensor and pressure ports

- New turbine wheel aero constructed of Mar-M alloy rated for 1055°C

- Stainless steel wastegated and non wastegated turbine housing option capable of 1050°C

- Oil restrictor and water fittings included

Compressor Aero

Forged fully-machined compressor wheel and new aerodynamics increase maximum horsepower output and boost response. The CFD (computational fluid dynamics) engineered compressor wheel increases air flow up to 15 per cent for 60mm and 30 per cent for 67mm with 79-80 per cent efficiency (compared to GTX Gen II).

Available in standard rotation and reverse rotation options for enthusiasts that want the perfect twin turbo installation or a single reverse rotation turbo for applications with installation restrictions.

Speed Sensor

The compressor housing features a fully machined ported shroud to help reduce compressor surge. A fully machined speed sensor port provides enthusiasts the option to add the new G Series speed sensor to measure turbocharger shaft speed, a key factor in determining ideal operating conditions.

The new speed sensor is easy to install and does not need to be adjusted for length like previous sensors. Simply remove and plug, then insert the speed sensor and tighten the bolt. The new speed sensor is sold separately and is not compatible with GT and GTX sensors due to the new design and sizing.

The addition of an o-ring between the compressor housing and backplate reduces the possibility of boost pressure leakage.

Centre Housing

A new one-piece centre housing and backplate increase durability and product safety by reducing the number of failure points associated with the turbocharger.

The centre housing to turbine housing v-band connection allows for 360-degree orientation when installing with Garrett® non-wastegated turbine housings.

Water Jackets

Four large water jacket ports increase cooling capacity and allow enthusiasts to customise water line routing to help improve the installation process. The turbocharger comes with two -6AN water fittings and two plugs.

*Recommended to install waterlines on opposite sides of the housing.

Oil Passage

A single stage oil passage directs pressurised oil to the new oil cavity ensuring proper bearing lubrication at both sides of the cartridge. Each turbocharger includes (1) -4AN oil restrictor fitting with a 1mm orifice to provide the turbo with the recommended 40psi of oil pressure.

Rotating Group – Twin Piston Rings

A shorter bearing cartridge allows Garrett to incorporate twin piston rings on both sides of the shaft wheel assembly. This will reduce the likeliness of oil leakage at the seals from the center housing to the compressor and or turbine stage

Turbine Wheel Aero

The turbine wheel features all new aerodynamics to improve flow and boost response. The new turbine wheel is made of Mar-M super alloy and is capable of handling exhaust gas temperatures up to 1050°C. The new turbine wheel flows 15-20 per cent more than GTX and has peak efficiency of 74 per cent.

Turbine Housings

All G Series Turbine housings are made from stainless steel to provide ultimate durability and temperature resistance up to 1050°C.

Internally wastegated housings are compact, efficient, and designed with maximum bypass port size to reduce boost creep and provide better boost control. Turbine housings are available in a variety of wastegated and non-wastegated, open volute, T25 and V-band configurations so be sure to order the correct part for your application.

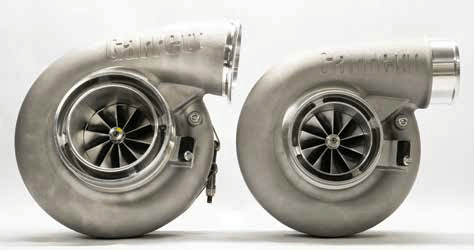

GARRETT® G42-1200 and G42-1450

GARRETT® G42-1200

Horsepower: 475 – 1200

Displacement: 2.0L – 7.0L

GARRETT® G42-1450

Horsepower: 525 – 1450

Displacement: 2.0L – 8.0L

Garrett® G Series 42 turbochargers offer enthusiasts a new range of quick spooling, high horsepower solutions for 2.0 litre up to 8.0 litre engine platforms. The G42-1200 Compact, G42-1200, and G42-1450 turbochargers produce up to 1450 horsepower thanks to the ten blade, forged, fully-machined G Series compressor wheel with high flowing aero. These low inertia compressor wheels are smaller in size and weight resulting faster boost response (compared to GTX42). Garrett® G42-1200 is available in standard V-band, and compact compressor housing options. The V-band compressor housing is outline interchangeable with GTX42 while the new Compact option is 4mm shorter axially and 29mm smaller radially.

The G Series turbine wheel features all new aerodynamics to improve flow and boost response. New turbine aero wheel flows 10 per cent more and has peak efficiency of 77 per cent (compared to GTX42 at 74 per cent with 1.01A/R). Engineered with inconel super alloy to withstand operating temperatures up to 950°C. Stainless steel turbine housings are available with V-band inlet and outlet connections in free float mono-scroll options. Divided, free float, T4 turbine housings will be available in 2019.

Features Include:

- Garrett® G series compressor aerodynamics for maximum horsepower

- Fully machined speed sensor and pressure ports

- New turbine wheel aero for increased efficiency and flow

- Stainless steel turbine housings

- Water fittings included

Compressor Aero

- CFD (computational fluid dynamics) engineered compressor wheel

- Optimised blade contour with 10 blade count

- Forged and fully-machined compressor wheel

- More power and faster boost response

- Smaller wheel = lower inertia

Compressor Housing

- Garrett® G42-1200 available with compact housing and standard housing

- Garrett® G42-1450 available only with standard housing

- Fully machined ported shroud to help reduce compressor surge

- A fully machined speed sensor port provides racers the option to add a speed sensor. Comparing shaft speed and boost.

- levels on a compressor map will help determine ideal operating conditions to ensure peak power over a wider operating range

- The fully machined pressure port. Sold separately, the Garrett® G Series speed sensor kits have new part numbers and are not compatible with GT/GTX kits. Easier to install and will not need to be adjusted for length like previous sensors. Simply remove bolt that secures the plug, insert the speed sensor and re-tighten the bolt

Speed Sensor Kits

G Series Street Kit:

781328-0003 (includes speed sensor, wire harness, gauge).

G Series Street Kit:

781328-0003 (includes speed sensor, wire harness, gauge). G Series Pro Kit: 781328-0004 (includes speed sensor, wire harness).

Centre Housing

- Aluminum backplate for reduced weight

- Includes (2) -6AN water fittings

- Center housing to turbine housing V-band connection makes installation easy for installers (same V-band as GTX42 / GTX45)

- GTX and GT turbine housings are not interchangeable

- Full 360 degree orientation of compressor housing and non wastegated turbine housings

- An o-ring between the compressor housing and backplate reduces any boost pressure leakage

Rotating Group

- Twin piston rings on both sides of the shaft reduce the likeliness of oil leakage from the center housing to the compressor or turbine stage

- A new oil deflector redirects oil away from the compressor stage seals reducing possibility of oil leakage through the seals

- 10mm ceramic dual ball bearing cartridge (same as GTX42)

G42 Turbine Aero

- The turbine wheel features all new aerodynamics to improve flow and boost response

- Inconel super alloy construction for temperatures up to 950°C

- New turbine wheel flows 10 per cent more and has peak efficiency of 77 per cent (compared to GTX42 at 74 per cent with 1.01A/R)

- 82mm inducer / 75mm exducer 84 Trim

G42 Turbine Housings

- G42 turbine housings are made from stainless steel to provide ultimate durability and temperature capability up 950°C or 1742 deg F

- B&C qualified

- GTX and GT housings not interchangeable

- Turbine housings are available in V-band, open, free float configurations for launch

- V-band inlet is 3.6 inch / 92mm (compared to GTX30/35 3 inch / 76mm)

- V-band outlet is 4.3 inch / 109mm

GTX Series

Garrett – Advancing Motionn GTX Series turbochargers are designed specifically for the hard-core enthusiast who wants optimal performance. The forged fully-machined billet aluminium compressor wheels feature next-generation aerodynamics that provides a larger horsepower range and maximise boost response. Ported shroud compressor housings increase surge resistance and provide reliable, continuous power throughout the power band.

A dual ceramic ball bearing cartridge prolongs the lifespan and improves shaft balance.

The water cooled CHRA keeps housing temperatures to a minimum. The turbine wheel is constructed from Inconel, a super alloy that maintains strength during prolonged exposure to high exhaust gas temperatures.

Turbine kits are offered in open volute and twin scroll, and a variety of A/R and flange configurations. GTX Series turbochargers are used by today’s top motorsports teams and are ready to boost you to the podium or wherever your destination may be.

GEN II Product Updates

Updated features on select GTX Turbochargers.

GEN II Compressor aerodynamics for increased horsepower range (GTX28/30/35/55)

- Gen II wheel produces 9 per cent more air flow

- 30 per cent lower inertia

- Reduced inertia due to reduction of material in the hub and blades

- Roughly 20 per cent lower mass

- Lower inertia helps make boost faster and increases overall turbo efficiency

- Increased flow has potential to make more power at same boost or same power at lower boost levels

Additional Features Include:

- Lightweight billet backplate (GTX47/50/55)

- (New) Backplate to compressor housing O-ring

- Speed sensor port compatible only with new flange style speed sensors: (pn 781328-0003 Street Kit | pn 781328-0004 Pro) (GTX28/35/47/50/55) – compatible only with New G Series Speed Sensor

GTX GEN II 2018 Updated Release Range GTX5544R Gen II

Horsepower: 1400 – 2850

Displacement: 3.0L – 12.0L

GTX5533R Gen II

Horsepower: 1000 – 2500

Displacement: 3.0L – 12.0L

GTX5020R Gen II

Horsepower: 1075 – 2050

Displacement: 2.8L – 11.0L

GTX5009R Gen II

Horsepower: 875 – 1700

Displacement: 2.5L – 10.0L

GTX4720R Gen II

Horsepower: 1025 – 1950 Displacement: 2.5L – 10.0L

GTX4709R Gen II

Horsepower: 825 – 1625 Displacement: 2.0L – 10.0L

See Garrett – Advancing Motion at the AAA Expo.