While in some instances it is immediately obvious that the injectors are not functioning correctly in a diesel fuel system, this might not always be the case.

There are a number of diagnostic tests which may suggest that injectors in a diesel fuel system may not be performing properly. At times, diagnosis may be difficult as the common rail fuel system will compensate for deficiencies within the system leading to fault codes that do not directly identify the injectors as being faulty.

Generally speaking the following diagnostic tests are carried out:

- Check the fuel quality in the fuel filter using a small jar and inspect with a LED torch– if metal, water or other contamination is found here – you will know that the entire fuel system will have to be cleaned and the fuel pump and injectors replaced or repaired; but if nothing is found here

- Check compensation levels with an electronic scan tool

- With no start, check injectors with electrical probes

- Injector operation should be assessed with a scan tool

- Perform a return leak measurement on the injectors

- Finally, remove the injectors for specialist diagnostic on a test bench which gives a comprehensive assessment of their operation

The ECU will use the injectors to compensate for each other and for various engine discrepancies. For example a 4-cylinder engine with 0-5 range, compensations above 2 is an indication of a problem.

Therefore a V8 will have a maximum compensation of 1 without indicating a problem. If the engine has a fault such as valve or compression leak, compensations will show high and can be incorrectly diagnosed as injector problems.

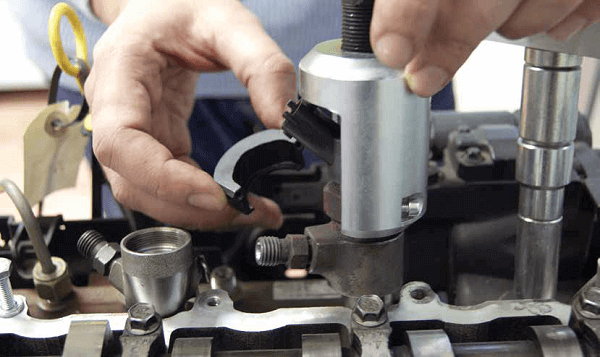

When removing injectors, the ultimate goal is to remove them without damaging them or other engine components. This allows the components to be tested independently of each other as well as saving a great deal of extra work and ultimately the cost of the repair.

Removing injectors without destroying any components can be a simple and easy job with the right tools and an understanding of the system you are working with, although some presentations can be very daunting – especially if there is a build-up of material around leaking injectors or simply the structure of the engine and the injectors themselves.

Generally, finding the correct tool that will attach to the injector and then using a slide hammer, hydraulic ram or other pulling arrangement to extract the injectors with the least amount of impact or jarring ensures their safe removal – then it is just a matter or ensuring that the recess is clean and that the injector seat is cut square to the perpendicular ensuring they sit without leaking in the recess when reinserting the new or remanufactured injectors.

Govoni Tools

Govoni Universal kit GO507 for injector removal, distributed by Specialist Tools Australia, is equipped with slide hammer, pliers, articulated joint adapter and special socket that will fit around the head of the injector (Bosch style). This kit allows the technician various options for the removal different types of injectors in a variety of vehicles commonly found in Australia where they are not excessively stuck.

Govoni tools are extremely robust, high performing Italian tools designed for the professional automotive technician looking for many years of reliable service from their tools, with the flexibility of being able to adapt the tools to different styles of injectors and engines.

At Specialist Tools Australia the team go beyond just selling tools. Their vast automotive diagnostic knowledge, especially with diesels, assists them in ensuring you get the right tool for your job.