RYCO Filters voted in Australia’s top most innovative companies.

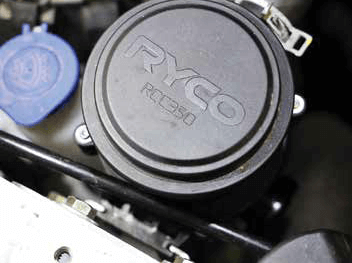

RYCO Filters has been voted in the top 5 of Australia’s most innovative companies in the 2019 Australian Financial Review AFR BOSS Most Innovative Companies Awards Manufacturing and Consumer Goods category. This prestigious award is in recognition of the research, development and successful market launch of the innovative RYCO RCC350 Crankcase Filter.

The RYCO product development team with direct customer input from the market had identified a concern with crankcase emissions contaminating engine air intake systems.

During operation, engines develop high internal pressures that must be released to avoid problems. This pressure build up is a mixture of harmful gasses such as oil vapour, that are vented to the engine via the PCV (positive crankcase ventilation) valve to the engine’s air intake system to prevent these emissions reaching the atmosphere. Over an extended period however this gas mixture sets on the inside walls of the intake system, not unlike cholesterol, preventing the engine from breathing properly. This results in a reduction in engine power, an increase in fuel consumption and can lead to expensive maintenance. To prevent this occurring, many simple and illegal actions are taking place in the market i.e. dismantling part of the emission system which results in increasing atmospheric pollution.

“As a company, RYCO articulates innovation as ‘Change that Adds Value’ and recognising this particular issue was getting worse, our aim was to fully understand the problem from the customers perspective. Using our close relationship with trade customers who could articulate the issue through specialist forums, one on one discussions and from careful observation on what was happening in the market, especially in the 4X4 diesel area, we uncovered several existing solutions which were either illegal or were completely ineffective and complex,” said RYCO General Manager Engineering and Innovation, Alastair Hampton.

“The trade clearly required an innovative solution that was easy to fit to a wide range of vehicles that offered effective filtration of these harmful gasses along with large capacity storage,” he said.

With detailed information now at hand the RYCO development team set about designing a filter system that connects to the vehicle’s engine PCV emission system allowing the harmful engine gases to flow through to a specially designed filter.

This would trap the contaminants such as fine oil droplets and coalesces them into larger droplets which then fall into a special storage sump for safe disposal.

To develop a practical innovative solution it was necessary for the RYCO technicians to review a range of technical papers on emissions and related ISO standards. From this a detailed technical specification was created to further guide the design process. Efficiency life and flow targets were set to the highest standards for a best in class outcome whilst design features were based on direct feedback from what customers wanted i.e. easy fitment to a variety of engine bays and locations on a vehicle and the highest storage capacity storage.

A number of 3D printed samples were used for early testing and also presented to mechanics for feedback on the critical areas. Subsequent design iterations were incorporated as a result of their valuable feedback.

Using one of the most sophisticated in-house filtration laboratories in the SE Asia region enabled a series of lab tests to be undertaken to objectively measure and compare the new system to existing systems on key performance areas that were highlighted in the technical specification data and ISO standard. This confirmed with a high degree of accuracy the development as having class leading contaminant removal efficiency, excellent gas flow and valve performance as well as good storage capacity.

Robust construction of the unit was also critical and following exhaustive testing and material selection, the final RCC350 is constructed using a high temperature resistant engineering polymer housing that contains the special filter media and valves to manage the internal gas pressure and flow. To meet the widest possible range of vehicle applications four different housing orientations were developed to fit various engine bays and a mounting bracket was specially designed to facilitate easy removal of the unit for inspection and servicing. A drain tap is included for easy draining or an optional drain tube can be added with a secondary tap if a remote drain option is required by the customer.

From the launch of this innovative filter the feedback from customers has been overwhelming with comments such as ‘easy to fit, ‘offers highest efficiency’, ‘has good storage capacity’ and ‘robust’ as the product exceeds the stringent technical and design specifications established by the RYCO team.

RYCO Filters continuous drive for innovation in new products was rewarded at a formal dinner in Sydney as a Top Ten Most Innovative Company and 3rd in the Manufacturing and Consumer Category with its advanced RCC350 Crankcase Filter.

“The company was excited to take the 3rd in category win against some very big names especially as there were more than 800 entries from Australia and New Zealand. The outcome is a win for our customers and a great compliment to the professional approach RYCO Filters takes in the development of new and innovative products that lead the market,” commented RYCO Filters General Manager Engineering and Innovation, Alastair Hampton.